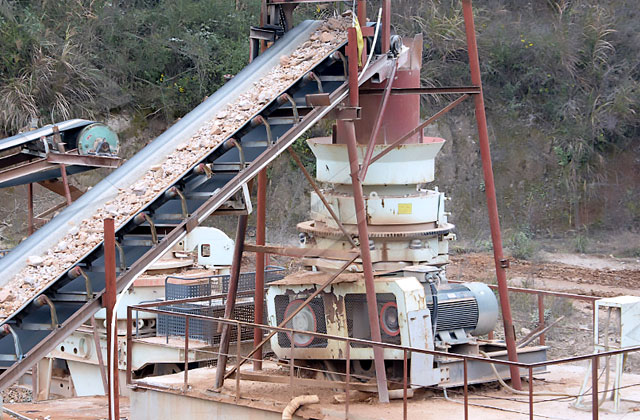

Quarrying is a vital industry that plays a significant role in the construction and infrastructure development of nations. In Vietnam, the demand for high-quality aggregates is surging due to the rapid urbanization and infrastructure projects. Cone crushers are widely recognized as essential equipment in the quarrying process, as they efficiently crush and process various types of rocks and minerals to produce high-quality aggregates. This article delves into the importance of cone crusher equipment in the Vietnamese quarrying industry and highlights how it contributes to increased efficiency and sustainability.

The Importance of Cone Crusher Equipment

Cone crushers are a type of compression crusher used in quarries to break down large rocks into smaller, more manageable sizes. Their design allows for the crushing of hard and abrasive rocks, ensuring the production of consistent and uniform aggregates. The primary advantages of cone crushers in the quarrying industry include:

a. High Efficiency: Cone crushers are designed to maximize productivity while reducing operating costs. Their robust build and advanced technology enable them to handle large volumes of material efficiently, minimizing downtime and maximizing production output.

b. Versatility: These crushers can process a wide range of materials, including limestone, granite, basalt, and many others. This versatility allows quarry operators in Vietnam to meet diverse market demands and produce aggregates for various applications.

c. High-Quality Aggregates: Cone crushers produce well-shaped and uniform aggregates, which are essential for ensuring the strength and durability of concrete and asphalt in construction projects.

Advanced Technologies Enhancing Performance

In recent years, the quarrying industry in Vietnam has witnessed significant advancements in cone crusher technology. Some of the key innovations include:

a. Automated Systems: Modern cone crushers are equipped with automated control systems that regulate the crusher’s settings and optimize performance. These systems help maintain consistent product quality and reduce the risk of equipment damage caused by operator error.

b. Eco-friendly Solutions: Environmental concerns are becoming increasingly important in the quarrying industry. Cone crusher manufacturers are now developing eco-friendly solutions by incorporating technologies such as dust suppression systems and energy-efficient motors, reducing the equipment’s environmental impact.

c. Wear-Resistant Components: The harsh conditions in quarries demand durable and wear-resistant components. Cone crusher manufacturers are using advanced materials and engineering techniques to prolong the lifespan of wear parts, reducing maintenance costs and downtime.