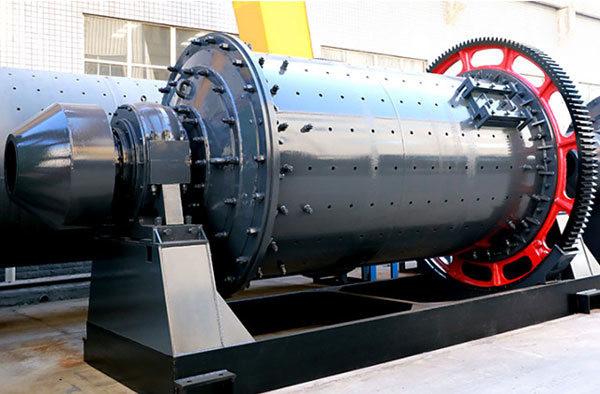

A ball mill is a versatile and commonly used mechanical equipment for grinding and blending materials in various industries. It works on the principle of impact and attrition: the size reduction is done by impact as the balls drop from near the top of the shell, and the attrition is the process of reducing particle size through friction between the balls. The materials processed in a ball mill can range from soft and delicate substances to hard and abrasive ones.

The standards for ball mills used in different industries vary based on the type of material being processed. In this article, we will discuss the general standards for ball mills used for various materials:

Ceramic Materials:

Ceramic materials are widely used in industries like pottery, tiles, and advanced ceramics. The ball mill standards for ceramics focus on the purity of the grinding media, the speed of milling, and the temperature during the milling process. The grinding media used must be non-contaminating to avoid any undesired impurities in the ceramic product. Additionally, controlled milling speeds and temperatures are essential to achieve the desired particle size distribution and prevent thermal damage to the ceramics.

Minerals and Ores:

Ball mills play a crucial role in the mineral processing industry, where they are used for ore grinding and liberation. For mineral and ore materials, standards focus on factors like the selection of appropriate grinding media, the percentage of solids in the mill, and the grinding time required to achieve the desired particle size for downstream processing.

Metals:

In metallurgy, ball mills are used for refining and alloying metals. The standards for metal materials consider factors such as the type and size of grinding media, milling time, and the use of inert atmospheres or protective coatings to prevent oxidation or contamination during milling. Control of milling parameters is crucial to obtaining the desired metal particle size and ensuring the structural integrity of the final metal product.

Chemicals:

The pharmaceutical and chemical industries employ ball mills for grinding, mixing, and homogenizing chemical substances. Ball mill standards for chemicals emphasize the use of inert materials for the grinding media and the avoidance of cross-contamination between different chemicals. Additionally, the design of the mill and its lining should be chemically resistant to the substances being processed.

Paints and Coatings:

Ball mills are commonly used in the paint and coating industry to disperse pigments and achieve the desired color and consistency. The standards for paint and coating ball mills emphasize the selection of grinding media that does not react with the paint components and the use of proper milling techniques to prevent agglomeration and achieve a uniform dispersion.