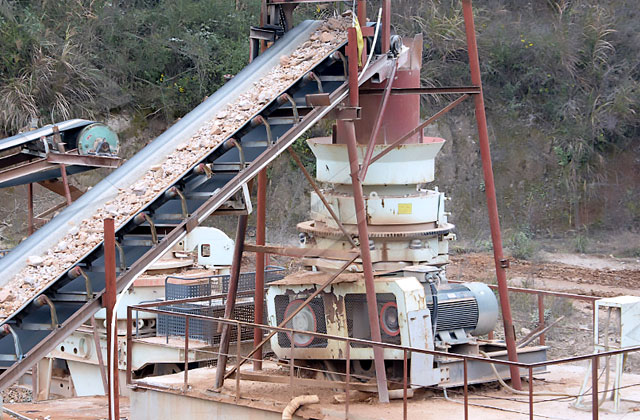

Non-metallic ore crushers are essential pieces of equipment used in mining and mineral processing operations to reduce the size of raw materials for further processing. These crushers play a critical role in extracting valuable minerals and preparing them for various industrial applications. One critical factor in the efficient operation of ore crushers is power consumption, as it directly impacts operational costs and environmental sustainability.

Power consumption in non-metallic ore crushers primarily depends on several key factors, including the type and design of the crusher, the characteristics of the ore being processed, the size distribution of the feed material, and the required final product size. Let’s explore these factors in more detail:

Crusher Type and Design:

Different types of crushers are used for crushing non-metallic ores, such as jaw crushers, cone crushers, impact crushers, and gyratory crushers. Each type has its unique design and operating principles, which can influence power consumption. For instance, jaw crushers are generally more energy-efficient than gyratory crushers, but the latter may produce a more uniform product.

Ore Characteristics:

The physical and chemical properties of the ore being processed significantly impact the power consumption. Harder ores require more energy to break, whereas softer ores are crushed more easily. Abrasiveness, moisture content, and density are crucial factors affecting power consumption.

Feed Size Distribution:

The size distribution of the feed material directly influences the power consumption of the crusher. Finer materials generally require less energy to be crushed, while coarser materials may demand more energy.

Final Product Size Requirements:

The desired final product size also plays a role in determining the power consumption. Crushers designed to produce smaller particles generally consume more power than those aimed at larger product sizes.

Crusher Settings and Maintenance:

Proper crusher settings, maintenance, and regular inspections can optimize the crusher’s performance and reduce power consumption. Ensuring that the crusher is always operating within its recommended parameters will prevent excessive energy usage and improve overall efficiency.