Ball mill power selection is a critical aspect in the design and optimization of grinding circuits in the mining industry. The power requirements of a ball mill depend on various factors, including the characteristics of the ore, the grinding process, and the equipment used. In this response, I will discuss the key considerations for selecting the appropriate ball mill power for mining applications.

Ore Characteristics:

The first step in ball mill power selection is to understand the characteristics of the ore being processed. Factors such as ore hardness, feed size distribution, and mineral composition can significantly influence the power requirements. Harder ores generally require more power to achieve the desired grinding fineness.

Grinding Process Requirements:

The grinding process objectives also impact the ball mill power selection. The desired product size, production rate, and grinding efficiency are crucial factors to consider. Finer grinding typically requires higher power input. Additionally, the type of grinding circuit (e.g., open circuit, closed circuit) and the presence of recirculating load can affect the power requirements.

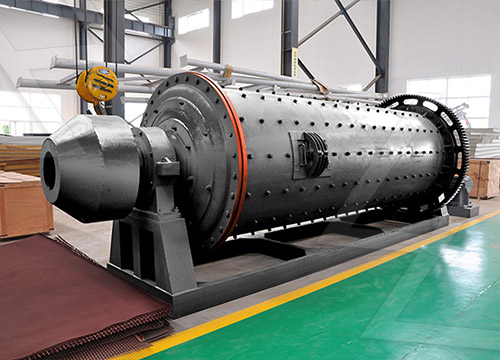

Equipment Specifications:

The specifications and efficiency of the ball mill itself play a vital role in power selection. Factors such as mill diameter, length, speed, and liner design influence the power requirements. Larger mills with higher diameters and lengths generally require more power. The mill speed affects the grinding kinetics, with higher speeds generally requiring more power. The selection of appropriate liner design can impact the mill’s efficiency and power consumption.

Operational Considerations:

Operational parameters also affect the power selection for a ball mill. The fill level of the mill, the load characteristics, and the pulp density in the mill all contribute to power requirements. Proper control and optimization of these parameters can help achieve the desired power consumption and overall performance.

To determine the optimal ball mill power selection, comprehensive testing and analysis are typically performed. This includes laboratory-scale tests, pilot-scale tests, and plant-scale trials to gather data on the ore properties, grinding performance, and power consumption. Based on the results, empirical models or advanced simulation tools can be used to estimate the power requirements for different operating conditions.