A granite crushing plant, also known as a stone crusher plant, is a facility designed to crush granite into smaller pieces or aggregates for various construction purposes. The process involves a series of stages where different machinery and equipment are utilized to achieve the desired outcome. I will provide an overview of a granite crushing plant and discuss its components, operation, and benefits.

A granite crushing plant typically consists of several components that work together to process the raw granite into usable materials. The primary component is the stone crusher machine, which is used to break down the large granite rocks into smaller pieces. These machines come in different types, such as jaw crushers, cone crushers, impact crushers, or hammer crushers, depending on the desired size and shape of the final product.

The raw granite rocks are usually extracted from quarries and then transported to the crushing plant. In the plant, the granite rocks are fed into the primary crusher, where they are initially reduced in size. The crushed granite then passes through secondary and tertiary crushers to further break it down into even smaller pieces.

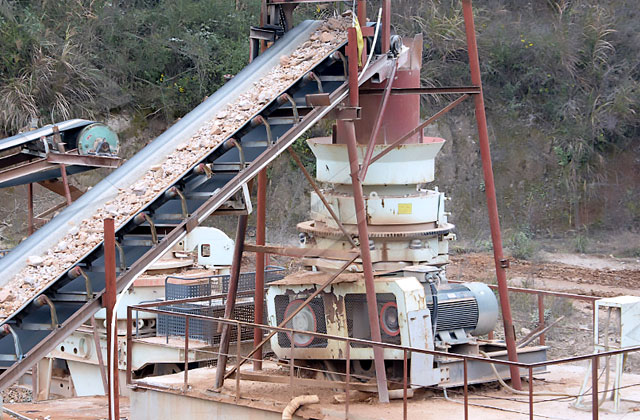

After the crushing process, the granite aggregates are sorted based on their size. They may go through a screening process to separate them into different categories, such as fine aggregates, coarse aggregates, or specific sizes required for particular construction applications. The screened granite is then stored in stockpiles or loaded directly onto trucks for transportation to construction sites. Apart from the stone crushers, a granite crushing plant also includes other essential equipment. These can include vibrating feeders, which regulate the flow of granite into the crushers, conveyor belts for efficient material transportation, and vibrating screens to further separate and categorize the crushed granite.

Granite is a popular choice in construction due to its durability, strength, and aesthetic appeal. It is widely used for building foundations, bridges, monuments, countertops, and decorative stone applications. A granite crushing plant plays a crucial role in providing the necessary materials for these construction projects.

Furthermore, a granite crushing plant can contribute to the local economy by creating job opportunities and generating revenue. The extraction and processing of granite involve a range of industries and services, including quarrying, transportation, equipment maintenance, and more.

Granite crushing plant plays a crucial role in the construction industry by processing raw granite into usable materials for various applications. It involves a series of stages, from primary crushing to sorting and screening, utilizing different types of machinery and equipment. A well-operated granite crushing plant offers durability, high-quality materials, recycling opportunities, and economic benefits to the local community.