A cone crusher is a crucial piece of equipment in the mining and aggregate industries. It is used to crush ore and rock into small pieces for further processing. To ensure the efficient and reliable operation of a cone crusher, regular maintenance and timely replacement of spare parts are essential. This is where cone crusher spare parts manufacturers play a vital role.

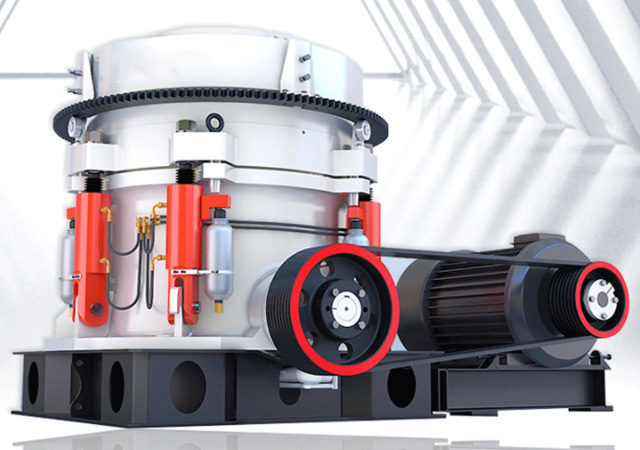

A cone crusher consists of several components, including the main frame, concave, mantle, eccentric shaft, bowl liner, and many others. Over time, these parts may wear out or become damaged due to the extreme conditions in which they operate. Therefore, cone crusher spare parts manufacturers produce high-quality replacements to ensure the uninterrupted functioning of the crusher.

Here are some key aspects to consider when discussing cone crusher spare parts manufacturers:

- Expertise and Experience: Reputable manufacturers have a team of skilled engineers and technicians who possess extensive knowledge and experience in cone crusher design and operation. They understand the specific requirements of different crusher models and work closely with their clients to provide suitable spare parts solutions.

- Quality Manufacturing: Reliable cone crusher spare parts manufacturers use advanced manufacturing techniques and high-quality materials to produce durable and precision-engineered components. They employ strict quality control measures at every stage of the manufacturing process to ensure that the parts meet or exceed industry standards.

- Comprehensive Product Range: A well-established manufacturer offers a comprehensive range of cone crusher spare parts to cover various brands and models. This includes parts such as concaves, mantles, eccentric bushings, spider bushings, main shafts, bearings, and more. The availability of a wide range of parts ensures that customers can find the exact replacements they need.

- Customization: In addition to standard spare parts, reputable manufacturers can also provide customized solutions to meet specific customer requirements. They can adapt the design and materials of the parts based on factors such as the application, feed size, operating conditions, and desired performance.

- Timely Delivery and Support: Efficient manufacturers understand the importance of timely delivery and provide quick turnaround times for spare parts orders. They have streamlined processes in place to minimize lead times and ensure that customers can get their equipment up and running as soon as possible. Additionally, they offer excellent customer support, including technical assistance, installation guidance, and troubleshooting services.

- Competitive Pricing: While the quality of spare parts is crucial, pricing also plays a significant role. Leading manufacturers offer competitive pricing without compromising on quality. They aim to provide cost-effective solutions to their customers, helping them minimize downtime and overall operating costs.

- Warranty and After-Sales Service: Reliable manufacturers stand behind the quality of their products and offer warranties on their spare parts. They also provide after-sales service and support to address any issues or concerns that may arise. This ensures peace of mind for customers and reinforces the manufacturer’s commitment to customer satisfaction.

In conclusion, cone crusher spare parts manufacturers play a crucial role in ensuring the efficient and reliable operation of cone crushers. They produce high-quality replacements that are designed to withstand the demanding conditions of mining and aggregate processing. By partnering with a reputable manufacturer, customers can secure the necessary spare parts to keep their cone crushers running smoothly, minimize downtime, and optimize their operations.