A construction sand and gravel crushing plant plays a vital role in the production of aggregates, which are essential materials in various construction projects. This plant is designed to process raw materials such as rocks, stones, and gravel into specific sizes that meet the requirements of different applications. In this article, we will explore the significance of a construction sand and gravel crushing plant and how it operates.

A construction sand and gravel crushing plant is a facility where raw materials are transformed into usable aggregates. These aggregates are widely used in the construction industry for building roads, bridges, houses, and other infrastructure projects. The process of crushing these raw materials involves several stages, including primary, secondary, and tertiary crushing.

The primary stage involves the use of a vibrating feeder that delivers the raw materials to a jaw crusher. The jaw crusher is responsible for reducing the size of the materials into smaller pieces. It uses a fixed and movable jaw plate to exert pressure on the rocks, breaking them into manageable sizes. The crushed materials then move to the secondary crushing stage.

In the secondary crushing stage, the materials are further reduced in size by a cone crusher or an impact crusher. These machines use a rotating cone or hammers, respectively, to crush the materials into even smaller fragments. The resulting aggregates are then sorted into different sizes using vibrating screens.

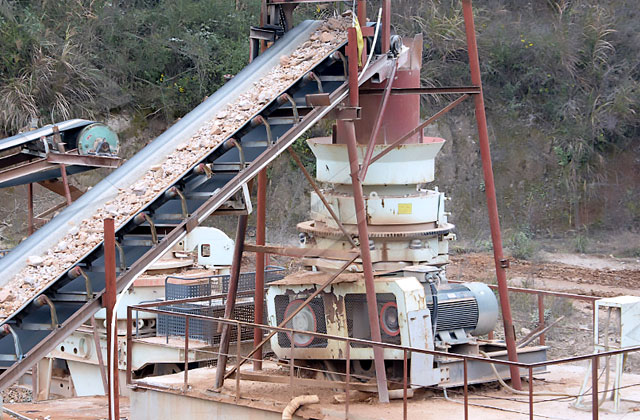

Once the aggregates have been sorted into their desired sizes, they proceed to the tertiary crushing stage. Here, the materials undergo additional crushing and shaping to achieve the desired specifications. Various types of crushers, such as vertical shaft impact crushers or tertiary impact crushers, are commonly used in this stage. These crushers refine the aggregates and ensure they meet the required quality standards.

After the crushing process, the aggregates are conveyed to storage bins or stockpiles. These stockpiles serve as temporary storage areas for the aggregates before they are transported to construction sites. The aggregates can be loaded onto trucks or railcars for delivery to their intended destinations.

A construction sand and gravel crushing plant requires proper maintenance and monitoring to ensure efficient and reliable operation. Regular inspections of the equipment, such as crushers, screens, and conveyors, are necessary to identify any potential issues and prevent breakdowns. Adequate lubrication and cleaning of the machinery are also essential to maintain optimal performance.

In conclusion, a construction sand and gravel crushing plant is a fundamental facility in the production of aggregates for the construction industry. By transforming raw materials into usable products, this plant supports the development of various infrastructure projects. Understanding the crushing process and implementing proper maintenance and environmental measures are key to ensuring the plant operates efficiently and sustainably.