Ball mills for non-ferrous metal powder production play a crucial role in various industrial processes. These mills are specially designed to grind and mix non-ferrous metal powders to create homogeneous blends with desired properties. In this article, we will explore the significance of ball mills, their working principles, and their applications in the production of non-ferrous metal powders.

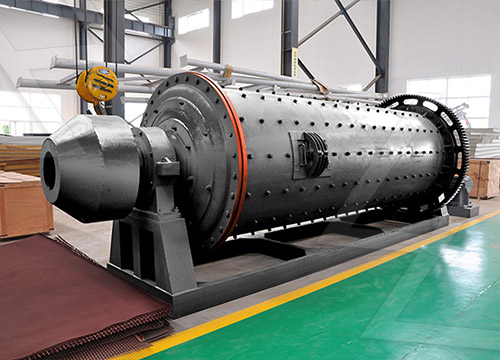

Ball mills are cylindrical devices that rotate around a horizontal axis and are partially filled with the material to be ground, along with grinding media such as ceramic balls, flint pebbles, or stainless steel balls. The rotation of the mill causes the grinding media to cascade and impact the material, resulting in the reduction of particle size. The grinding action promotes intimate mixing of the components and facilitates the production of a fine powder.

Non-ferrous metal powders are powders that do not contain iron as the primary constituent. These powders are widely used in various industries, including aerospace, automotive, electronics, and metallurgy. Examples of non-ferrous metal powders include aluminum, copper, zinc, tin, and lead powders, among others. The production of these powders requires careful control of particle size, shape, and composition to meet specific application requirements.

Ball mills offer several advantages for the production of non-ferrous metal powders. Firstly, they provide a high-energy grinding environment, which leads to the efficient reduction of particle size. The grinding action is accompanied by intense mixing, resulting in a homogenous powder blend. Additionally, ball mills can be operated in a wet or dry mode, providing flexibility in processing different types of materials. Wet grinding can help in controlling the particle size distribution and prevent agglomeration of fine particles.

The selection of the appropriate ball mill for non-ferrous metal powder production depends on various factors, including the desired particle size, the properties of the starting materials, and the process requirements. The size and material of the grinding media, as well as the rotational speed of the mill, are critical parameters that affect the grinding efficiency and final powder characteristics. The mill design and construction should be robust to withstand the grinding forces and ensure long-term operation.

In conclusion, ball mills are essential equipment for the production of non-ferrous metal powders. These mills provide efficient grinding and mixing of materials, resulting in the formation of homogeneous blends with controlled particle size distributions. The versatility of ball mills allows for processing various non-ferrous metals, catering to the diverse needs of industries such as aerospace and automotive. With ongoing advancements in milling technology, ball mills continue to play a vital role in the production of non-ferrous metal powders, driving innovation and enabling the development of advanced materials for a wide range of applications.