Limestone is a common sedimentary rock composed mainly of calcium carbonate (CaCO3). It is widely used in construction, agriculture, and other industries due to its various applications and desirable properties. To process limestone efficiently, crushers and mills play a crucial role. In this article, we will discuss the importance of crushers and mills in limestone processing.

Crusher for Limestone Processing:

Crushers are machines designed to reduce large rocks into smaller rocks, gravel, or rock dust. In limestone processing, crushers are used to break down the limestone into manageable sizes for further processing. There are several types of crushers commonly used for limestone crushing:

- Jaw Crusher: This is a primary crusher that crushes the limestone by squeezing it between an eccentrically gyrating spindle and a stationary piece of steel. It is ideal for processing medium-hard to hard limestone.

- Impact Crusher: An impact crusher uses the principle of rapid impact to crush the limestone. It utilizes hammers or blow bars that strike the material and break it into smaller pieces. Impact crushers are suitable for processing limestone with low to medium hardness.

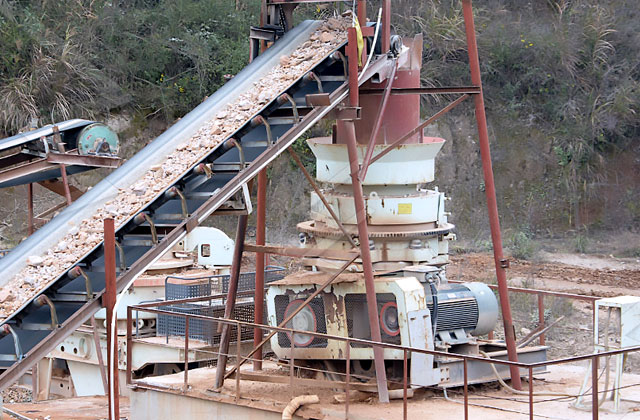

- Cone Crusher: A cone crusher operates on the principle of compression crushing. It uses a rotating mantle within a concave chamber to squeeze and crush the limestone. Cone crushers are often used in the secondary or tertiary crushing stages.

Each type of crusher has its advantages and is suitable for specific limestone processing requirements. The selection of the crusher depends on factors such as the hardness of the limestone, the desired output size, and the capacity requirements.

Mill for Limestone Processing:

After the limestone is crushed by the crusher, it needs to be ground into a fine powder for various applications. Limestone mills are used for this purpose. The two main types of mills used for limestone grinding are:

- Raymond Mill: Raymond mill is a commonly used limestone grinding mill that mainly grinds limestone into powder by the grinding roller. It has higher grinding efficiency and lower power consumption than the ball mill.

- Ball Mill: A ball mill is a type of grinder used to grind and blend materials for use in mineral processing and other industries. It works on the principle of impact and attrition. In the case of limestone processing, the ball mill grinds the limestone into a fine powder.

The choice between a Raymond mill and a ball mill depends on the desired particle size, the specific surface area requirements, and other factors. Raymond mills are generally used for finer grinding, while ball mills are suitable for coarser grinding.

In limestone processing, both crushers and mills are essential equipment. The crusher breaks down the limestone into manageable sizes, while the mill grinds it into a fine powder. These processes enable the limestone to be used in various applications such as construction materials, cement production, agriculture, and more.

Crushers and mills play a vital role in limestone processing. The crusher reduces the limestone into smaller sizes, and the mill further grinds it into a fine powder. This processed limestone can be utilized in a wide range of industries, making it a valuable resource for economic development.