Iron ore beneficiation is a process that involves the removal of impurities from iron ore to improve its quality. The process involves crushing, screening, washing, grinding, and magnetic separation. The process flow sheet is a key component in the design of any beneficiation plant and is used to determine the optimal flow of material through the plant.

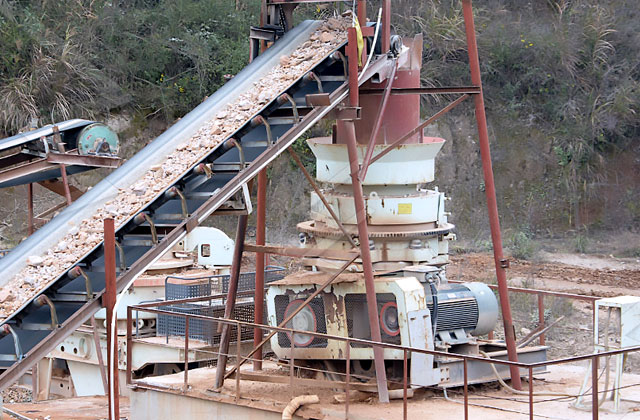

The first step in the iron ore beneficiation process is crushing and screening. This involves breaking the ore into small pieces and then screening it to remove any oversized material. The ore is then washed to remove any remaining impurities.

After washing, the ore is ground to a fine powder using a ball mill or other grinding equipment. This process is known as grinding and is used to reduce the size of the ore particles to a level where they can be separated from the impurities.

The next step in the process is magnetic separation. This involves using a magnetic separator to separate the iron ore from the impurities. The magnetic separator uses a magnetic field to attract the iron ore particles and separate them from the impurities.

Once the iron ore has been separated from the impurities, it is ready for further processing. This involves drying the ore to remove any remaining moisture and then pelletizing it. Pelletizing involves forming the iron ore into small pellets that can be used in the steel-making process.

The final step in the iron ore beneficiation process is shipping. The pellets are loaded onto ships and transported to steel mills where they are used to make steel. The steel-making process involves melting the pellets in a blast furnace and then refining the molten iron to produce steel.

The process flow sheet for iron ore beneficiation can vary depending on the type of ore being processed and the desired end product. However, the basic process is similar and involves the same steps. The key to a successful beneficiation plant is to design a process flow sheet that is optimized for the specific ore being processed and the desired end product.

In conclusion, the iron ore beneficiation process flow sheet is a key component in the design of any beneficiation plant. It is used to determine the optimal flow of material through the plant and to ensure that the process is efficient and effective. The process involves crushing, screening, washing, grinding, and magnetic separation, and is used to remove impurities from the iron ore to improve its quality. The final product is shipped to steel mills where it is used to make steel.