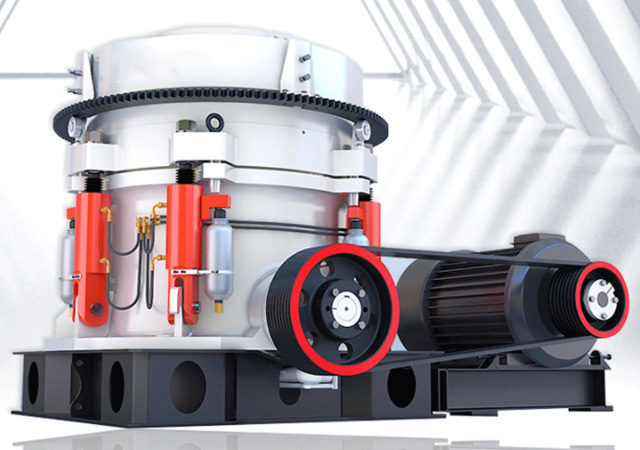

A cone crusher is a type of crushing equipment used in mining and aggregate industries. It is commonly used in secondary, tertiary, and quaternary crushing stages in various applications. The cone crusher has several advantages over other crushing equipment, including high efficiency, low energy consumption, and uniform particle size distribution. In this article, we will discuss the performance and advantages of cone crusher.

Performance of Cone Crusher:

- High Crushing Ratio: Cone crushers are designed to crush a variety of materials, from hard and abrasive rocks to soft and friable ones. They are capable of producing a high reduction ratio of up to 6:1, which means fewer stages of crushing are required to produce the desired size of material.

- Efficient Operation: Cone crushers operate on the principle of compressive crushing, which reduces the size of the material by squeezing it between two surfaces. This results in a more efficient operation as compared to other types of crushers, such as jaw crushers or impact crushers, which use the principle of impact crushing.

- Uniform Particle Size Distribution: The cone crusher produces a more uniform particle size distribution as compared to other types of crushers. This is because the crushing action takes place between the surfaces of the mantle and concave, which results in a more uniform size distribution of the crushed material.

- Low Maintenance: Cone crushers are designed to be low maintenance machines, with few moving parts and easy access for maintenance. This makes them a cost-effective choice for crushing operations, as they require less maintenance and downtime than other types of crushers.

- Versatility: Cone crushers are versatile machines that can be used in a wide range of applications. They are commonly used in the mining, aggregate, and construction industries, and can be used for secondary, tertiary, and quaternary crushing.

Advantages of Cone Crusher:

- High Efficiency: Cone crushers are highly efficient machines that can reduce the size of material by up to 80%. This means that less energy is required to crush the material, resulting in lower energy consumption and operating costs.

- Low Operating Costs: Cone crushers have low operating costs, as they require less maintenance and repair than other types of crushers. Additionally, they are designed to be highly efficient, which means that less energy is required to operate them.

- Uniform Product Size: Cone crushers produce a more uniform product size, which is important for many applications. This is because the crushing action takes place between the surfaces of the mantle and concave, which results in a more uniform size distribution of the crushed material.

- High-Quality Product: Cone crushers produce a high-quality product, which is important for many applications. This is because they are designed to crush the material in a way that results in a more uniform size distribution of the crushed material, which can improve the quality of the final product.

- Safe and Reliable: Cone crushers are designed to be safe and reliable machines, with a range of safety features to protect the operator and the machine. This includes features such as hydraulic adjustment, automatic overload protection, and a range of other safety features.

Cone crushers are highly efficient, versatile machines that are capable of producing a high-quality product with a uniform particle size distribution. They are cost-effective, low-maintenance machines that are ideal for a wide range of crushing applications in the mining, aggregate, and construction industries. Their high efficiency, low operating costs, and versatility make them a popular choice for crushing operations around the world.