In the realm of ore mining and processing, the efficiency and effectiveness of crushing operations play a pivotal role in determining overall productivity. Cone crushers stand as essential equipment in this domain, offering a versatile solution for reducing large chunks of raw material into smaller, manageable sizes. Moreover, the strategic export of cone crushers can significantly impact global mining operations, fostering efficiency, sustainability, and economic growth. This article delves into the significance of cone crusher export in optimizing ore mining and processing.

The Role of Cone Crushers in Ore Mining and Processing:

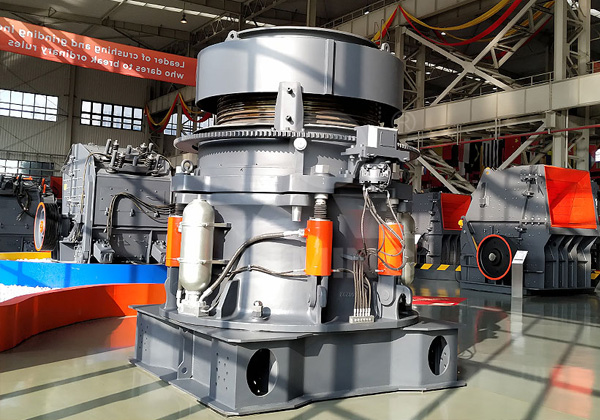

Cone crushers are robust machines designed to handle various types of ores, rocks, and minerals. Their ability to crush materials efficiently makes them indispensable in primary, secondary, and tertiary crushing stages. Cone crushers utilize a rotating mantle within a concave bowl to compress material against the mantle, effectively reducing it in size. This process ensures uniformity in particle size distribution, essential for downstream processing.

Enhancing Efficiency Through Cone Crusher Export:

Exporting cone crushers to regions with burgeoning mining industries can yield several benefits. Firstly, it facilitates the adoption of advanced crushing technology in emerging markets, thereby enhancing operational efficiency and productivity. Secondly, exporting cone crushers can contribute to standardizing mining practices globally, promoting best practices in ore processing. This process is particularly effective for hard and abrasive ores, making cone crushers a preferred choice in the mining industry.

One of the primary benefits of cone crushers is their versatility. They can be deployed across a wide range of applications, from primary crushing to secondary and tertiary stages. Whether it’s crushing large chunks of ore into smaller fragments or refining the final product to meet specific size requirements, cone crushers excel in delivering consistent performance across diverse scenarios.

Moreover, cone crushers boast exceptional throughput capacity, allowing for the processing of large volumes of ore within a relatively short timeframe. This high throughput is attributed to their robust construction, efficient design, and advanced technological features. As a result, mining operations can achieve higher production rates while minimizing downtime, thereby maximizing overall efficiency.

Another advantage of cone crushers is their ability to produce uniform end products with minimal fines generation. This is essential for ore processing plants, where the quality of the final product directly impacts downstream processes such as flotation, leaching, and smelting. By producing well-graded materials, cone crushers facilitate better ore recovery and metallurgical performance, ultimately optimizing the overall process efficiency.

Technological Advancements and Innovation:

The export of cone crushers stimulates technological advancements and innovation in the mining equipment sector. Manufacturers strive to develop more efficient, durable, and environmentally friendly cone crusher designs to meet the evolving needs of the global mining industry. This continuous innovation cycle benefits both producers and end-users, fostering a culture of progress and sustainability.