Algeria, a country rich in natural resources and diverse landscapes, has been witnessing a growing demand for construction materials, particularly sand and gravel. As the construction industry expands to meet the needs of a growing population and infrastructure development, the demand for high-quality aggregates has intensified. In response to this demand, Algeria has invested in state-of-the-art sand and gravel crushing equipment to boost its capacity and efficiency.

The 200t/h sand and gravel crushing equipment represents a significant milestone in Algeria’s efforts to enhance its construction material production capabilities. This cutting-edge equipment is designed to process large volumes of raw materials, ensuring a steady and reliable supply of aggregates for various construction projects.

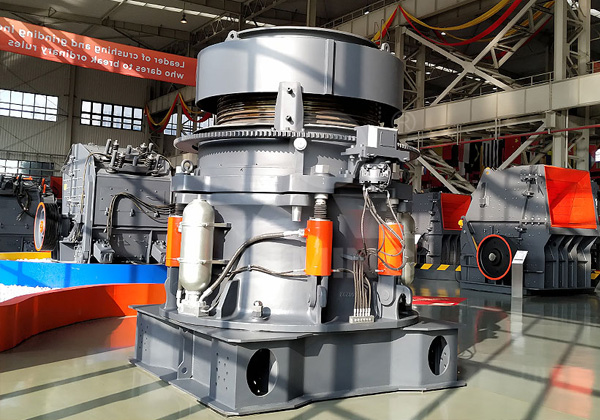

The primary component of the crushing equipment is a robust jaw crusher, capable of handling the toughest materials with ease. Equipped with advanced technology, this crusher efficiently breaks down large rocks into smaller, manageable sizes. The high crushing capacity of 200t/h ensures that the production meets the ever-growing demands of the construction industry.

Complementing the jaw crusher is a sophisticated screening system that separates the crushed materials into different sizes. This precision screening process guarantees the production of aggregates with uniform particle sizes, meeting the stringent quality standards required for construction applications. The efficiency of the screening system contributes to minimizing waste and maximizing the yield of high-quality aggregates.

To further enhance the efficiency of the sand and gravel crushing process, the equipment is equipped with advanced automation and control systems. These systems optimize the operation of the machinery, ensuring a smooth and continuous production flow. Automation also contributes to minimizing downtime, reducing operational costs, and enhancing overall safety in the production environment.

The 200t/h sand and gravel crushing equipment is designed with environmental sustainability in mind. Dust suppression systems are integrated into the machinery to minimize airborne particles, creating a safer and more eco-friendly workplace. Additionally, water recycling systems are implemented to reduce water consumption, aligning with global efforts to promote responsible resource usage.

Algeria’s investment in this advanced crushing equipment not only addresses the current demand for aggregates but also positions the country for future growth in the construction sector. The enhanced production capacity and efficiency contribute to the overall economic development of Algeria by supporting infrastructure projects, housing developments, and other construction initiatives.