Jaw crushers and cone crushers are two fundamental types of primary crushers used in mining, quarrying, and recycling industries. They play a crucial role in breaking down large rocks into smaller, more manageable pieces. Let’s explore the capacities of jaw crushers and cone crushers, highlighting their key features, advantages, and applications.

Jaw Crusher:

A jaw crusher is a primary crusher that utilizes a set of “jaws” to crush hard and large materials into smaller pieces. The crushing process involves the movement of the jaws, which create compressive forces to break the material. Key features of jaw crushers include:

- Capacity: Jaw crushers come in various sizes, and their capacity is often measured in terms of the feed opening size. Larger feed openings generally result in higher capacity.

- Advantages:

- Simple structure and easy maintenance.

- Efficient at handling abrasive materials.

- Ideal for primary crushing applications.

- Applications:

- Primary crushing in mining and quarrying.

- Recycling of construction and demolition waste.

- Crushing various types of ores and rocks.

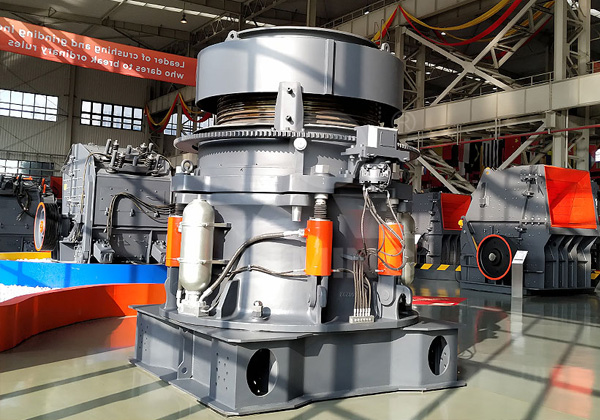

Cone Crusher:

Cone crushers, on the other hand, operate on the principle of compression crushing. These crushers have a conical-shaped bowl and a mantle, both of which move in a gyratory motion to squeeze the material between them. Key features of cone crushers include:

- Capacity: Cone crushers are known for their high capacity and efficiency. The capacity is influenced by the size of the discharge opening and the eccentricity of the mantle.

- Advantages:

- High crushing ratio and efficient particle size distribution.

- Good for secondary and tertiary crushing stages.

- Versatility in various applications.

- Applications:

- Secondary and tertiary crushing in mining and aggregate industries.

- Production of high-quality end products in construction.

- Processing hard and abrasive materials.

Capacity Comparison:

The capacity of both jaw crushers and cone crushers can vary widely depending on factors such as the type of material, feed size, and desired final product size. Generally, cone crushers are often preferred for higher capacity requirements, especially in secondary and tertiary crushing stages. However, jaw crushers can still offer substantial capacity and are more suitable for certain applications.

In summary, the choice between a jaw crusher and a cone crusher depends on the specific requirements of the application. While jaw crushers are excellent for primary crushing and handling abrasive materials, cone crushers offer higher capacity and efficiency, making them suitable for secondary and tertiary crushing. Understanding the material characteristics and the desired end product will aid in selecting the most appropriate crusher for a given operation.