Stone crushers play a crucial role in the construction and mining industries, breaking down large rocks into smaller, more manageable sizes for various applications. The design and development of stone crushers are critical factors in ensuring their efficiency, safety, and environmental sustainability. This article delves into the key aspects of designing and developing stone crushers, considering both technological innovations and environmental considerations.

Key Design Considerations:

- Material Selection: The choice of materials for constructing stone crushers is pivotal. Robust materials that withstand the harsh conditions of mining and construction environments are essential. High-strength alloys, wear-resistant steel, and advanced composites are commonly employed to ensure durability and longevity.

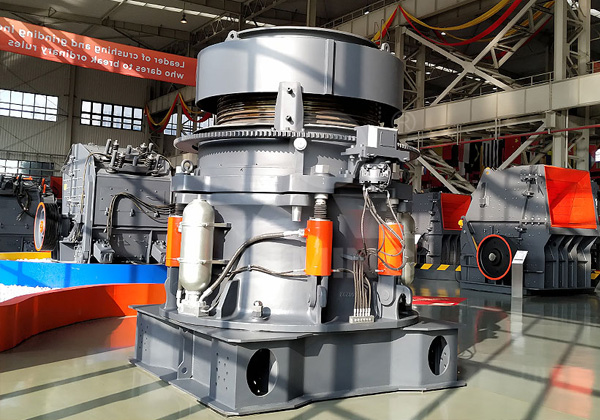

- Crushing Mechanism: Various crushing mechanisms exist, including jaw crushers, cone crushers, impact crushers, and gyratory crushers. Selecting the right mechanism depends on the type and size of the rocks being processed. A well-designed crushing chamber and optimized crushing angles contribute to better efficiency and reduced wear on components.

- Power and Efficiency: Stone crushers require sufficient power to break down rocks effectively. Innovations in powertrain technology, such as energy-efficient engines and advanced transmission systems, contribute to reducing fuel consumption and operational costs while maintaining high crushing efficiency.

- Automation and Control Systems: Integrating automation and control systems improves the operational efficiency and safety of stone crushers. Advanced sensors, real-time monitoring, and feedback mechanisms allow for precise control of the crushing process, reducing the risk of overloading and optimizing energy consumption.

Environmental Considerations:

- Dust Suppression Systems: Dust emissions during the crushing process can have adverse effects on both the environment and human health. Incorporating effective dust suppression systems, such as water sprays or chemical agents, helps mitigate these impacts, ensuring compliance with environmental regulations.

- Noise Reduction: Stone crushers can generate significant noise pollution, impacting nearby communities and wildlife. Implementing noise reduction technologies, such as sound barriers and acoustic enclosures, contributes to a more sustainable and socially responsible operation.

- Emission Control: Internal combustion engines used in stone crushers can emit pollutants. Employing state-of-the-art emission control technologies, such as catalytic converters and particulate filters, reduces the environmental footprint of the crushers, aligning with global emission standards.

Innovation and Technology:

- Digital Twin Technology: The integration of digital twin technology allows for virtual simulations and real-time monitoring of stone crushers. This enables predictive maintenance, early fault detection, and optimization of performance, leading to increased operational reliability.

- Materials Science Advances: Ongoing developments in materials science contribute to the creation of more durable and lightweight components for stone crushers. Nanotechnology and advanced metallurgy enhance the strength and wear resistance of critical parts.

The design and development of stone crushers require a holistic approach that balances technological innovation with environmental sustainability. By focusing on robust materials, efficient crushing mechanisms, and incorporating advanced technologies for automation, control, and environmental management, the industry can create stone crushers that are not only high-performing but also environmentally responsible. As the demand for construction materials continues to rise, a commitment to responsible design and development practices is essential for a sustainable future.