In the realm of mining and mineral processing, crushers play a crucial role in breaking down large rocks and minerals into smaller, more manageable pieces. Algeria, endowed with significant mineral resources, relies on efficient crushing technology to extract valuable materials. Among the various types of crushers employed in the mining industry, primary and secondary crushers are integral components in the ore processing chain.

Primary Crushers:

Primary crushers are the initial stages of the crushing process, tasked with reducing the size of raw materials extracted from the earth. Their primary function is to handle large chunks of rock or ore and prepare them for subsequent processing. In Algeria, primary crushers are pivotal in the extraction of minerals such as iron ore, gold, copper, and phosphate.

One of the most commonly used primary crushers is the jaw crusher, renowned for its robustness and versatility. Jaw crushers consist of a fixed jaw and a movable jaw, wherein the material is compressed between the jaws to achieve the desired size reduction. These crushers are adept at handling various types of ores, from soft to extremely hard, making them indispensable in Algerian mining operations.

Another prevalent type of primary crusher is the gyratory crusher, characterized by its large size and high capacity. Gyratory crushers operate by gyrating the mantle within a concave bowl, exerting compression on the feed material. This crushing action enables efficient reduction of bulky materials, making gyratory crushers suitable for primary crushing applications in Algeria’s mining sector.

Secondary Crushers:

Secondary crushers follow primary crushers in the crushing circuit and further refine the material to attain the desired size for downstream processes. While primary crushers focus on initial size reduction, secondary crushers ensure finer granularity, enhancing the liberation of valuable minerals. In Algeria, secondary crushers are instrumental in achieving optimal mineral recovery and processing efficiency.

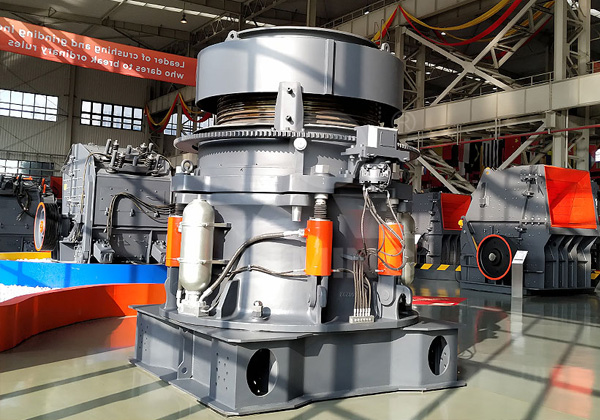

One of the commonly employed secondary crushers is the cone crusher, renowned for its ability to produce finely crushed materials. Cone crushers utilize a rotating mantle within a concave bowl to exert compression on the feed material, resulting in the production of uniform-sized particles. These crushers are indispensable in Algeria’s mining operations, particularly in the production of aggregates for construction and the processing of industrial minerals.

Impact crushers also play a vital role as secondary crushers in Algerian mining operations. Impact crushers operate by imparting kinetic energy to the feed material, causing it to break upon impact with fixed or rotating hammers. This crushing mechanism enables the production of consistent-sized aggregates and minerals, contributing to the overall efficiency of mineral processing plants.

In Algeria’s mining industry, primary and secondary crushers are indispensable components in the ore processing chain. From the initial reduction of raw materials to the refinement of finely crushed particles, crushers facilitate the extraction and processing of valuable minerals. Jaw crushers, gyratory crushers, cone crushers, and impact crushers are among the primary and secondary crushers employed in Algerian mining operations, each playing a crucial role in achieving optimal mineral recovery and processing efficiency. As Algeria continues to harness its mineral wealth, the importance of efficient crushing technology remains paramount in maximizing resource utilization and sustaining economic growth.