A mining cone crusher is a crucial part of the ore processing chain in mining operations. It plays a vital role in reducing large rocks into smaller, more manageable pieces, facilitating further processing and extraction of valuable minerals. In Algeria, a country rich in natural resources like oil, natural gas, and various minerals, the mining cone crusher is an essential tool for the efficient and sustainable extraction of these resources.

Algeria boasts a diverse range of minerals, including iron ore, phosphate, zinc, lead, and gold, among others. The mining industry in the country has witnessed significant growth in recent years, with increasing investments in exploration and extraction projects. In this context, the mining cone crusher stands out as a key equipment in the crushing and processing of mined materials.

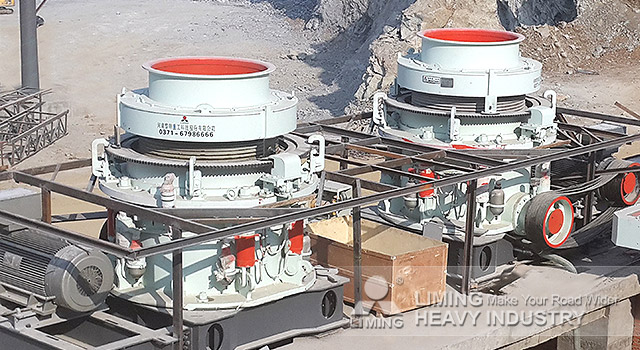

The primary function of a mining cone crusher is to break down large rocks into smaller, more manageable pieces through the use of compression, impact, or shear forces. The machine’s design includes a concave surface and a mantle, which are crucial components for crushing efficiency. As the cone crusher operates, the rocks are fed into the crusher cavity, where they are crushed between the mantle and concave.

Algerian mining companies understand the importance of investing in high-quality cone crushers to ensure the reliability and productivity of their operations. Modern cone crushers come equipped with advanced features such as hydraulic systems, which allow for easy adjustment of the crusher settings, ensuring optimal performance based on the type of ore being processed. This adaptability is crucial in handling varying ore characteristics and optimizing the overall efficiency of the crushing process.

One notable advantage of cone crushers is their ability to produce a well-graded product with a more uniform particle size distribution. This is essential for downstream processes, such as grinding and milling, where consistent feed size contributes to overall process efficiency. The cone crusher’s versatility extends to various ore types, making it a versatile and valuable asset in the mining industry.

In addition to efficiency and versatility, cone crushers also contribute to safety in mining operations. Advanced automation and remote monitoring systems enable operators to control and monitor the crusher from a safe distance, minimizing exposure to potential hazards. This is particularly important in large-scale mining operations where safety is a top priority.

As the mining industry in Algeria continues to evolve and expand, the role of cone crushers in ore processing will remain crucial. Their ability to handle a wide range of materials, produce a well-graded product, and contribute to overall process efficiency positions them as indispensable equipment in the mining sector. With ongoing advancements in technology, mining cone crushers will likely continue to play a key role in the sustainable and efficient extraction of Algeria’s mineral resources.