Kazakhstan, a Central Asian country known for its vast mineral resources, has been a key player in the global mining industry. With rich deposits of various minerals, including coal, iron ore, copper, gold, and more, the country has witnessed significant growth in its mining sector. Mineral processing, a crucial step in extracting valuable minerals from ores, involves the use of crushers. These crushers play a fundamental role in breaking down large rocks into smaller, more manageable pieces, facilitating the subsequent stages of mineral extraction.

One of the primary challenges in mineral processing is the efficient and effective comminution of ores. Comminution refers to the process of reducing the size of ore particles to expose valuable minerals and make them suitable for further processing. Crushers are essential equipment in this stage, as they break down the mined ore into smaller fragments. In Kazakhstan, where mining operations are widespread, the use of crushers is integral to the success of mineral processing plants.

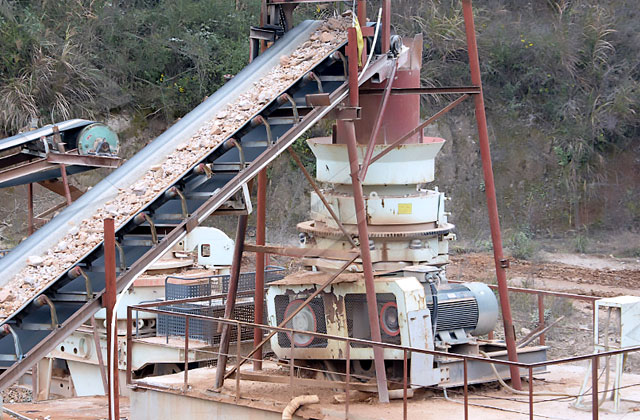

Various types of crushers are employed in mineral processing, each designed for specific applications and ore characteristics. Common types include jaw crushers, gyratory crushers, cone crushers, and impact crushers. Jaw crushers are often used for primary crushing, while cone and gyratory crushers are typically employed for secondary and tertiary crushing stages. Impact crushers, on the other hand, are versatile and can be used for primary, secondary, or tertiary crushing depending on the application.

In Kazakhstan, jaw crushers are commonly used for primary crushing in mineral processing plants. These crushers consist of a fixed jaw and a movable jaw, with the material being crushed by the reciprocal movement of the jaws. The efficiency of jaw crushers in primary crushing contributes significantly to the overall success of mineral processing operations.

Gyratory crushers, another important type, are characterized by a cone-shaped crushing head that rotates eccentrically within the crushing chamber. These crushers are often preferred for large mining operations due to their high capacity and ability to handle tough ores. In Kazakhstan, where large-scale mining projects are prevalent, gyratory crushers are employed for their robust design and high throughput capabilities.

Cone crushers, with their cone-shaped crushing chambers, are widely used for secondary and tertiary crushing. They are suitable for processing various types of ores and are essential in achieving the desired particle size for downstream processes. The versatility of cone crushers makes them valuable in diverse mineral processing applications in Kazakhstan.

Impact crushers are utilized for their ability to produce cubic-shaped end products and are often used in the final stages of mineral processing. These crushers use impact force to break down the material, making them suitable for softer ores or materials with lower abrasiveness.

Kazakhstan’s commitment to sustainable mining practices and technological advancements is reflected in the adoption of modern crushers with enhanced efficiency and reduced environmental impact. Advanced technologies, such as automation and remote monitoring, are increasingly integrated into mineral processing crushers, improving safety, optimizing operations, and reducing downtime.

Crushers play a pivotal role in the mineral processing industry in Kazakhstan. They are crucial for efficient comminution, which is essential for liberating valuable minerals from ores. The choice of crusher type depends on the specific characteristics of the ore and the desired end product. As Kazakhstan continues to be a key player in the global mining landscape, the efficient utilization of mineral processing crushers will remain vital for the sustainable extraction of its abundant mineral resources.