A mineral low capacity grinding mill is a specialized equipment designed to process and grind minerals into fine powders. These mills are crucial in various industries such as mining, metallurgy, cement, and chemical processing, where the reduction of particle size is essential for optimizing downstream processes. The term “low capacity” indicates that these mills are suitable for smaller-scale operations or applications where a lower throughput is sufficient.

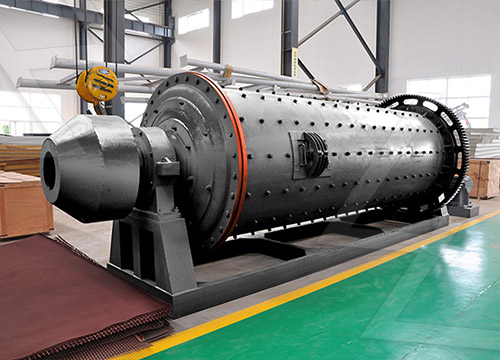

One common type of mineral low capacity grinding mill is the ball mill. Ball mills are cylindrical devices that rotate around a horizontal axis, partially filled with the material to be ground and the grinding medium (usually steel balls or ceramic beads). The rotation of the mill causes the material to be ground by the impact and friction between the grinding media and the particles.

The low capacity of these mills makes them suitable for laboratory or pilot plant settings, as well as small-scale production scenarios. Despite their lower throughput compared to larger mills, they are valuable for research, testing, and processing smaller quantities of minerals.

There are several key features and considerations associated with mineral low capacity grinding mills:

- Size and Design:

- Low capacity mills are generally smaller in size compared to their high-capacity counterparts. They are often designed for easy installation, operation, and maintenance.

- The design may include features such as a simple structure, easy access for maintenance, and a straightforward grinding chamber configuration.

- Material Feed and Discharge:

- These mills typically have a controlled material feed mechanism to regulate the flow of minerals into the grinding chamber.

- Discharge systems vary and may include overflow discharge or grate discharge, depending on the specific design of the mill.

- Grinding Media:

- The choice of grinding media is crucial for achieving the desired particle size reduction. Commonly used media include steel balls, ceramic beads, or other specialized grinding media.

- The size and composition of the grinding media can be adjusted based on the hardness and abrasiveness of the minerals being processed.

- Drive Systems:

- Low capacity grinding mills may use simple drive systems, such as gear and pinion arrangements. The power required is generally lower compared to larger mills.

- Control Systems:

- Modern mills often incorporate advanced control systems to optimize the grinding process. This may include monitoring of parameters such as mill speed, feed rate, and slurry density.

- Applications:

- Mineral low capacity grinding mills find applications in various industries, including mineral processing, ceramics, and pharmaceuticals. They are used for tasks such as sample preparation, small-scale production, and experimentation.

Mineral low capacity grinding mills play a vital role in industries that require the processing of minerals into fine powders on a smaller scale. Their design, features, and applications are tailored to meet the specific needs of laboratory settings, pilot plants, and small-scale production environments. While they may have lower throughput compared to larger mills, their importance in research, development, and smaller-scale operations cannot be overstated.