A cone crusher is a type of secondary and tertiary crusher used in aggregate, mining, and industrial operations. It is known for its high efficiency and versatility in crushing various types of materials, including iron ore. With technological advancements, cone crushers have evolved to become more efficient, reliable, and adaptable to different operating conditions. This article will discuss the high efficiency of iron ore cone crushers, their key features, and their contribution to the mining and aggregate industries.

Cone crushers are designed to crush hard and abrasive materials, making them ideal for processing iron ore. Their efficient crushing capabilities make them popular in various industries, including mining and construction. High efficiency in an iron ore cone crusher can be attributed to several key factors, including design, technology, and operational parameters.

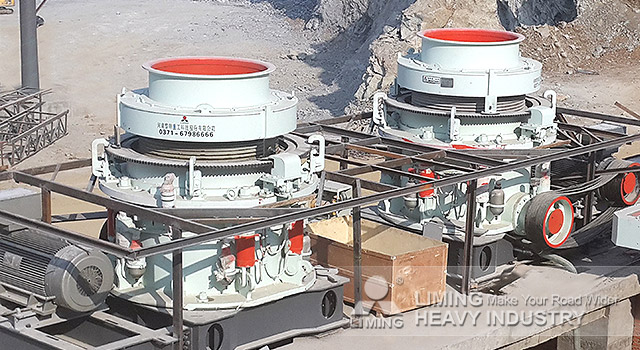

Advanced Design: Manufacturers have continuously improved the design of cone crushers to enhance their efficiency. These designs often incorporate features such as optimized crushing chambers, eccentric throw, and a high pivot point. Additionally, the use of high-quality materials in the construction of these machines ensures their durability and reliability in crushing demanding materials like iron ore.

Crushing Technology: Advanced crushing technologies, such as the use of high-speed and high-throw eccentric mechanisms, contribute to the efficient crushing of iron ore. Additionally, the incorporation of hydraulic systems for adjusting the crusher settings and controlling the discharge opening enables operators to achieve the desired product size with minimal downtime and optimal efficiency.

Enhanced Operating Parameters: Efficient cone crushers for iron ore applications often operate at higher speeds and wider settings to maximize their throughput capacity. These optimized operating parameters, along with the use of advanced automation and control systems, allow for precise control over the crushing process, leading to higher efficiency and better product quality.

Versatility and Adaptability: Modern cone crushers are designed to handle various types of materials and can be easily adapted to different applications and operating conditions. This versatility allows for the efficient processing of different types of iron ore, including both magnetite and hematite, and enables operators to adjust the crusher settings to achieve the desired product specifications.

Maintenance and Serviceability: Manufacturers prioritize the ease of maintenance and serviceability of cone crushers to minimize downtime and ensure continuous operation. Features such as easy access to critical components, robust construction, and comprehensive maintenance platforms contribute to the overall efficiency and longevity of cone crushers used in iron ore processing.

The high efficiency of cone crushers in processing iron ore plays a crucial role in the mining industry’s efforts to meet the growing demand for this essential raw material. By optimizing design, incorporating advanced technology, and focusing on operational efficiency, manufacturers continue to develop cone crushers that offer improved performance, reduced operating costs, and increased productivity, ultimately contributing to the sustainable development of the mining sector.