Iran, with its rich geological diversity, is home to numerous quarries and mining operations that extract a wide range of materials, including limestone, granite, marble, and more. These quarries play a crucial role in the construction and infrastructure development of the country. One essential piece of equipment in quarrying operations is the cone crusher. This article explores the significance of cone crushers in Iranian quarries and highlights their features, benefits, and applications.

Cone Crushers in Quarrying

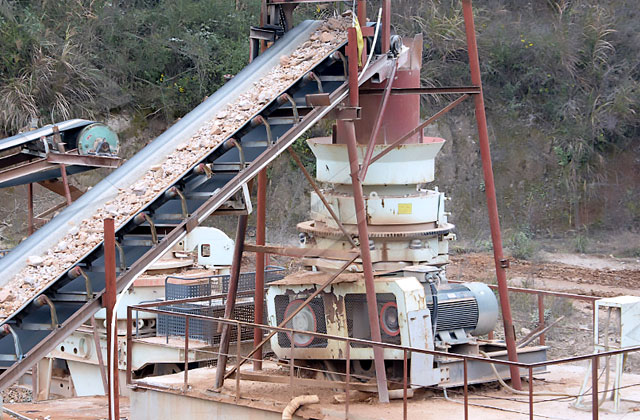

Cone crushers are a fundamental component of quarry equipment in Iran and worldwide. They are primarily used for secondary and tertiary crushing of various materials extracted from quarries. Cone crushers consist of a concave liner and a mantle, both of which are capable of crushing rocks and minerals by compressing them between the mantle and concave. The crushed material is then discharged through the bottom opening.

Key Features of Cone Crushers

Crushing Efficiency: Cone crushers are known for their high crushing efficiency, making them suitable for reducing large rocks into smaller, more manageable sizes. This efficiency helps in optimizing quarry operations.

Versatility: Cone crushers can handle a wide range of materials, from soft and brittle to hard and abrasive. This versatility is crucial in quarries where various types of rocks and minerals are extracted.

Adjustable Settings: Quarry operators can adjust the settings of cone crushers to achieve the desired product size, ensuring that the crushed material meets the specifications required for specific construction projects.

Wear Resistance: Cone crusher components are designed to withstand wear and tear, making them durable for long-term use in the harsh conditions of a quarry.

Benefits of Cone Crushers in Iranian Quarries

Improved Product Quality: Cone crushers produce well-shaped, cubical end products, which are highly desirable in the construction industry. This ensures that the material extracted from quarries meets quality standards.

Increased Productivity: Cone crushers can process large volumes of material quickly, contributing to higher productivity in quarry operations.

Cost Savings: The efficiency of cone crushers can lead to cost savings by reducing the need for additional crushing stages and minimizing downtime.

Environmental Benefits: Quarry operators in Iran are increasingly focused on environmental sustainability. Cone crushers help minimize the environmental impact by reducing the need for blasting, which can generate dust and noise pollution.

Applications of Cone Crushers in Iranian Quarries

Aggregates Production: Cone crushers are extensively used in the production of aggregates for construction purposes, such as road construction, concrete production, and building projects.

Mineral Processing: In addition to aggregates, cone crushers are utilized for crushing various minerals extracted from quarries, including limestone, gypsum, and dolomite.

Dimension Stone: Cone crushers are used to process dimension stone, such as granite and marble, into slabs and blocks for the construction and architectural industries.

Mining Operations: Some quarries in Iran also extract metallic minerals, and cone crushers are employed to crush ore for further processing.

In the Iranian quarrying industry, cone crushers are indispensable equipment that significantly contributes to the extraction and processing of various materials. Their efficiency, versatility, and durability make them a valuable asset in meeting the country’s construction and infrastructure development needs. As the industry continues to grow, cone crushers will likely play an even more prominent role in ensuring the success and sustainability of quarry operations in Iran.