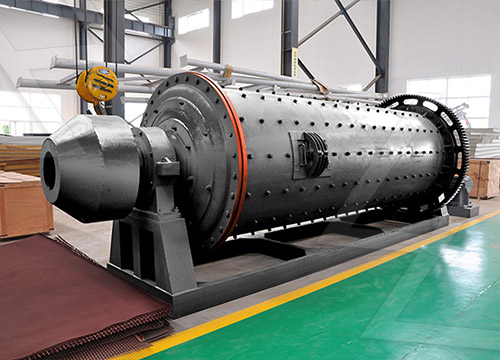

A cement ball mill assembly plays a crucial role in the process of grinding and blending various raw materials to produce cement. This equipment is commonly used in the cement and mining industries for grinding materials such as ores, clinker, and gypsum into fine powder, which is essential for cement production. The assembly consists of several components that work together to achieve efficient and reliable grinding operations.

Shell:

The shell is a cylindrical structure that houses the grinding media and the materials to be ground. It is typically made of steel and is lined with various materials to protect against wear and tear caused by the grinding process.

Mill Liners:

The inner surface of the shell is lined with mill liners, which are replaceable wear-resistant liners that protect the shell from abrasion caused by the grinding media and the processed materials. Liners also help optimize the grinding process by promoting proper lifting and cascading of the grinding media.

Grinding Media:

Grinding media are the balls or cylpebs that are used to perform the grinding action. These are made of various materials such as steel, ceramic, or other alloys. The choice of grinding media depends on the type of material being ground and the desired fineness of the final product.

Drive System:

The drive system consists of the motor, gearbox, and other components that provide the necessary power to rotate the mill. This rotation of the mill causes the grinding media to tumble and create an impact, crushing, and grinding the materials.

Girth Gear and Pinion:

The girth gear is a large ring gear that is mounted around the circumference of the mill shell. It is driven by the pinion gear, which is connected to the motor’s gearbox. The interaction between the girth gear and pinion rotates the mill shell and ensures the even distribution of forces and torque.

Inlet and Outlet:

The mill has an inlet for introducing the raw materials and a discharge outlet for the ground product. The design of these components ensures a smooth flow of materials through the mill.

Separator System:

In some cases, a separator system is integrated into the mill assembly to separate the fine material from the coarse material during the grinding process. This helps in achieving the desired fineness of the cement product.

Bearings and Lubrication:

Proper bearing arrangements and lubrication systems are essential for ensuring smooth and reliable operation of the mill. Bearings support the rotating components and help reduce friction and wear.

Control and Monitoring:

Modern cement ball mills often include advanced control systems and sensors that monitor various parameters such as mill speed, temperature, and power consumption. This data is used to optimize the grinding process and ensure efficient operation.