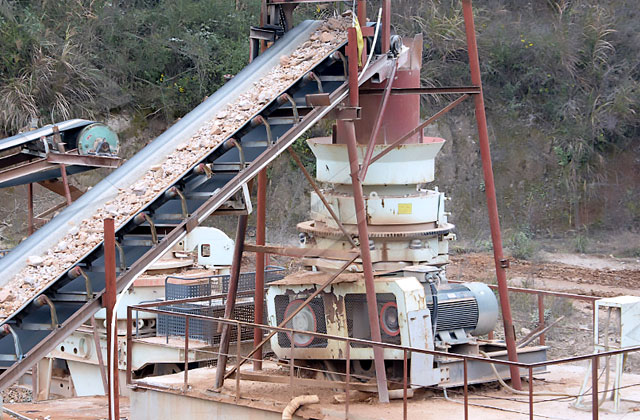

A large capacity quarry cone crusher is a vital machine in the mining and quarrying industry. It is used to break and crush rocks into smaller pieces for further processing. This crushing process ensures that the valuable minerals or materials are extracted efficiently and effectively for various industrial applications. In this essay, we will explore the significance of a large capacity quarry cone crusher, its components, working principle, advantages, and its role in modern quarry operations.

Significance of a Large Capacity Quarry Cone Crusher:

In the realm of mining and quarrying, efficient crushing equipment is paramount to the success of operations. A large capacity quarry cone crusher plays a crucial role in this process by enabling the processing of vast amounts of raw material. Whether it’s limestone, granite, basalt, or other types of rocks, the crusher’s ability to break them down into smaller sizes is the foundation of downstream operations.

Components and Working Principle:

A typical large capacity quarry cone crusher comprises several key components. The primary ones include:

- Mantle and Concave: These are the wear-resistant surfaces that come into contact with the rocks. The mantle gyrates eccentrically, causing the rocks to be crushed against the concave.

- Eccentric Shaft and Bearings: The eccentric shaft, driven by a motor, creates a circular motion that initiates the crushing process. Bearings facilitate smooth rotation.

- Crushing Chamber: This is the space between the mantle and concave where the actual crushing takes place.

- Feed Hopper and Feeding Mechanism: Raw materials are fed into the crusher through the hopper, and a feeding mechanism regulates the material flow.

- Hydraulic System: Many modern cone crushers use hydraulic systems to adjust the crusher’s settings and control the crushing process for optimal performance.

The working principle involves the eccentric motion of the mantle causing compressive forces that crush the rocks between the mantle and concave. As the rocks become smaller, they pass through the narrow opening at the bottom of the crusher.

Advantages of a Large Capacity Quarry Cone Crusher:

- High Production Capacity: As the name suggests, a large capacity cone crusher can process a significant volume of material, contributing to higher production rates.

- Versatility: Cone crushers can handle a wide range of materials and produce different particle sizes, making them versatile for various applications.

- Uniform Particle Size: The crushing process in cone crushers results in a more uniform particle size distribution compared to other crushing methods.

- Energy Efficiency: Modern cone crushers are designed to be energy-efficient, contributing to reduced operating costs.

- Automation and Control: Advanced control systems and automation features allow operators to optimize crusher performance and adjust settings in real time.

Role in Modern Quarry Operations:

In modern quarry operations, a large capacity cone crusher is a cornerstone of efficient material processing. Its ability to crush rocks into precise sizes ensures the production of high-quality aggregates used in construction, road building, concrete production, and other industries. Moreover, cone crushers contribute to sustainable mining practices by maximizing resource utilization and minimizing waste.