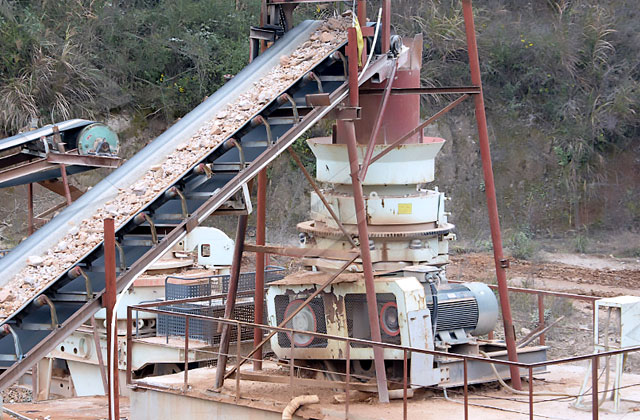

In the modern construction and mining industries, quarry cone crushers have emerged as essential equipment for efficiently crushing and processing various types of materials. A quarry cone crusher is a heavy-duty machinery designed to reduce large rocks into smaller-sized aggregates, making it suitable for a wide range of applications, including road construction, building materials, and mining operations. As demand for high-quality aggregates continues to grow, finding the right quarry cone crusher for sale is of paramount importance. This article explores the key features and benefits of high-quality quarry cone crushers, along with the factors to consider when purchasing one.

Superior Performance

High-quality quarry cone crushers are engineered to deliver exceptional performance. They are equipped with robust components, precision manufacturing, and advanced technology that ensures efficient and reliable crushing operations. These crushers can handle various types of materials, ranging from soft to hard rocks, with ease. Their high crushing capacity and steady production output contribute to increased productivity and reduced downtime, making them an indispensable asset for any quarry or mining operation.

Optimal Design and Durability

High-quality quarry cone crushers are built with durability in mind. The design incorporates reinforced steel structures and premium quality materials, ensuring long-lasting performance under challenging working conditions. The heavy-duty construction allows the machine to withstand harsh impacts and vibrations, prolonging its service life and minimizing maintenance requirements.

Energy Efficiency

Modern quarry cone crushers are engineered to be energy-efficient. Advanced technologies, such as variable-speed drives, automated control systems, and optimized crushing chambers, help reduce energy consumption while maintaining optimal performance. By minimizing energy wastage, these crushers not only contribute to cost savings but also reduce their environmental impact.

Versatility in Applications

A high-quality quarry cone crusher can adapt to various applications, making it a versatile tool for different industries. From producing high-quality aggregates for construction projects to processing ores in mining operations, these machines are designed to meet diverse crushing requirements. They can handle a wide range of feed sizes and produce various output sizes, enhancing their flexibility and usability.

Safety Features

Safety is of utmost importance in any industrial setting. Reputable quarry cone crushers come equipped with advanced safety features, including emergency stop buttons, protective guards, and automatic overload protection. These features safeguard operators and maintenance personnel, preventing accidents and ensuring a secure working environment.

Factors to Consider When Purchasing a Quarry Cone Crusher

Production Capacity: Consider the required throughput and select a crusher with an appropriate production capacity to match your operational needs.

Feed Size: Ensure that the crusher can handle the maximum feed size of the material you intend to process.

Crushing Efficiency: Evaluate the crusher’s crushing efficiency to guarantee optimal performance and minimize operational costs.

Maintenance and Service: Choose a model with accessible components and easy maintenance procedures to reduce downtime and enhance productivity.

Manufacturer Reputation: Buy from a reputable manufacturer known for producing reliable and high-quality quarry cone crushers.

Warranty and Support: Check the warranty terms and the availability of customer support for after-sales service and technical assistance.