Cone crushers play a crucial role in the mining and construction industries, as they efficiently break down large rocks into smaller particles for further processing. The pursuit of high efficiency in crushing operations has been a constant endeavor in the industry to enhance productivity and reduce operating costs. In this context, Australian engineering has made remarkable strides, creating cutting-edge high-efficiency cone crushers that stand at the forefront of global innovation.

Overview of Cone Crushers

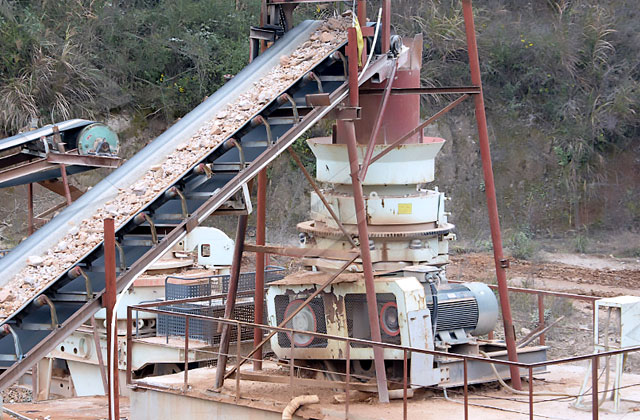

Cone crushers are robust machines designed to handle the toughest of materials. They consist of a cone-shaped crushing chamber and an eccentrically rotating mantle. The materials are fed into the crushing chamber through the top and are crushed between the mantle and the concave liner, which forms the outer surface of the chamber. The crushed material then exits through the bottom of the crusher.

The Need for High Efficiency Cone Crushers

With increasing demand for metals, minerals, and construction aggregates, the mining and construction industries require crushers that can process larger quantities of material while maintaining high levels of productivity. High efficiency in cone crushers translates into reduced energy consumption, better particle shape, and higher throughput, ultimately resulting in improved profitability for businesses.

Advantages of Australian High-Efficiency Cone Crushers

Advanced Crushing Technology: Australian cone crushers feature state-of-the-art technology, including advanced hydraulic systems, precision manufacturing, and intelligent control systems. These innovations enable efficient and reliable crushing operations, even under challenging conditions.

Optimal Cavity Design: The shape and depth of the crushing chamber significantly influence the performance of a cone crusher. Australian engineers have perfected the cavity design to ensure uniform crushing and consistent product gradation, thereby enhancing overall efficiency.

Enhanced Power and Capacity: These high-efficiency cone crushers are built to handle larger feed sizes and possess the power to process higher tonnages, enabling operations to increase their productivity without compromising on quality.

Wear-Resistant Components: Australian cone crushers are equipped with durable wear-resistant components, such as manganese liners, that reduce maintenance downtime and extend the machine’s lifespan, providing a cost-effective solution for operators.

Eco-Friendly Solutions: Many Australian cone crushers incorporate advanced technologies that contribute to reducing environmental impact. They aim to improve energy efficiency and minimize emissions, aligning with global efforts towards sustainability.