Granite is a popular and highly sought-after construction material known for its durability, strength, and aesthetic appeal. To extract granite from quarries and convert it into usable construction materials, stone crusher machines are employed. These machines play a crucial role in the process of crushing granite into smaller pieces that can be used for various construction purposes.

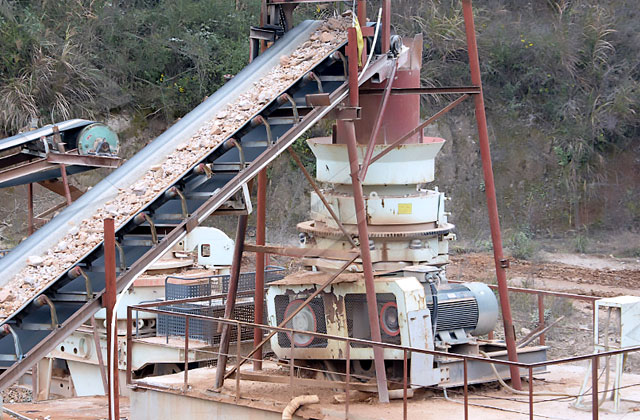

A stone crusher machine used for crushing granite typically consists of a vibrating feeder, primary jaw crusher, secondary cone crusher or impact crusher, vibrating screen, and belt conveyor. The process begins with the granite being fed into the vibrating feeder, which ensures a consistent and controlled flow of the material into the jaw crusher.

The primary jaw crusher is responsible for reducing the size of the granite rocks to a manageable size. It applies compressive force to break down the larger stones into smaller pieces. The crushed granite then passes through the secondary cone crusher or impact crusher, which further reduces its size.

The choice between a cone crusher and an impact crusher depends on factors such as the desired final product size, the hardness of the granite, and the specific requirements of the construction project. Cone crushers are often preferred for finer crushing, while impact crushers are suitable for producing a more cubical-shaped product.

After the secondary crushing stage, the crushed granite is sorted by size using a vibrating screen. This screen separates the different sizes of crushed granite, ensuring that the final product meets the specifications required for construction. The oversized granite pieces are sent back to the crusher for further crushing.

Once the granite has been appropriately sized and screened, it is ready for use in construction projects. The crushed granite can be used as a base material for roads, driveways, and walkways. It is also commonly used in the construction of buildings, bridges, and other structures.

The durability and strength of granite make it a popular choice for construction applications. It is resistant to weathering, erosion, and the impact of heavy loads, making it ideal for long-lasting and robust structures. Additionally, the natural beauty of granite adds an aesthetic appeal to construction projects, enhancing their overall visual appeal.