A stone crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. It is commonly used in mining, construction, and recycling industries. The capacity of a stone crusher is usually measured in terms of tons per hour. In this case, you are referring to a stone crusher with a capacity of 200 tons per hour.

A stone crusher with a 200-ton-hour capacity can process a substantial amount of material within a given time frame. It is commonly used in large-scale mining operations or construction projects where a high volume of crushed stone is required. The actual capacity may vary depending on factors such as the type of material being crushed, the feed size, and the desired final product size.

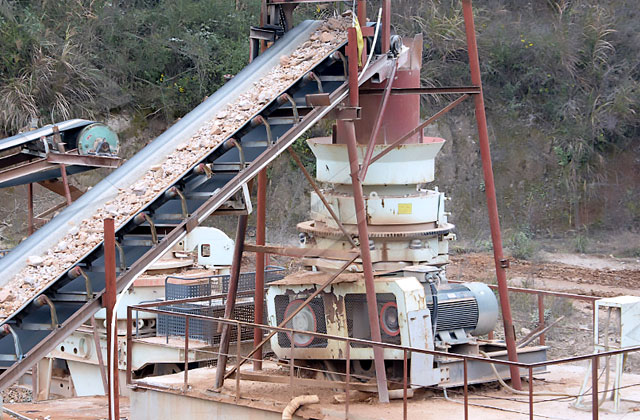

To achieve a 200-ton-hour capacity, a stone crusher typically consists of several components, including a primary crusher, secondary crusher, screens, conveyors, and a control system. Here is a breakdown of the process:

Primary Crushing: The primary crusher is responsible for breaking down the large rocks into smaller pieces. It is usually a jaw crusher or a gyratory crusher that applies compressive force to the material. The crushed material is then conveyed to the next stage.

Secondary Crushing: The secondary crusher further reduces the size of the crushed material. It can be a cone crusher, impact crusher, or another type of crusher depending on the specific requirements. The secondary crushing process produces smaller-sized stones that are ready for further processing.

Screening: After secondary crushing, the crushed material is often passed through screens to separate different sizes of stones. This step ensures that the final product meets the desired specifications. The screened material is then conveyed to the next stage.

Conveying: Conveyors are used to transport the crushed and screened material between different stages of the crushing process. They help to maintain a continuous flow of material and optimize efficiency.

Control System: A control system is implemented to monitor and control the operation of the stone crusher. It ensures that the machine operates within the desired parameters and helps to prevent any potential issues or overloads.

In conclusion, a stone crusher with a 200-ton-hour capacity can process a significant amount of material efficiently. It involves several stages, including primary crushing, secondary crushing, screening, conveying, and control. By effectively managing these processes, a stone crusher can meet the demands of various industries and contribute to the production of crushed stone for different applications.