A vibrating screen for sand and gravel aggregate is a crucial component of construction and mining operations. It’s essential for separating materials based on size and ensuring a uniform mixture of particles. This equipment plays a significant role in various industries, from building infrastructure to producing concrete.

Functionality and Design: The primary function of a vibrating screen in the context of sand and gravel aggregate is to separate the larger particles from the smaller ones. This separation is achieved by using a vibrating mechanism that causes the material to move across the screen deck. Typically, the screen is inclined at an angle to facilitate the movement of the material.

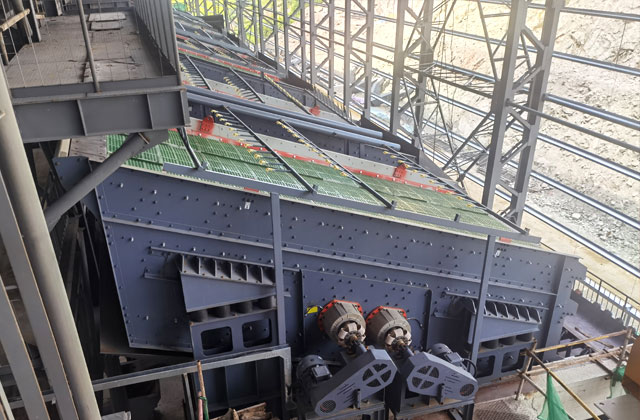

The design of a vibrating screen for sand and gravel aggregate involves several key elements:

- Screen Deck: This is the surface on which the material is placed for screening. It consists of a series of panels or sections with apertures of different sizes. The size of the apertures determines the size of the particles that can pass through.

- Vibrating Mechanism: This is the component responsible for generating the vibration that moves the material across the screen deck. It usually consists of eccentric weights or motors mounted on the screen box.

- Screen Box: This is the main structural component of the vibrating screen, housing the screen deck and the vibrating mechanism. It’s typically made of steel and designed to withstand the forces generated during operation.

- Support Structure: The vibrating screen is mounted on a support structure, which can be stationary or mobile, depending on the application. The support structure must be robust enough to support the weight of the screen and withstand the dynamic forces generated during operation.

Operation: During operation, the vibrating screen is fed with a mixture of sand and gravel aggregate. The larger particles are retained on the screen deck, while the smaller particles pass through the apertures and are collected underneath.

The vibrating mechanism generates a continuous vibration that causes the material to move across the screen deck. This movement helps to stratify the material, with the larger particles rising to the top and the smaller particles settling to the bottom.

As the material moves across the screen deck, it encounters the apertures, which act as sieves, allowing particles smaller than the aperture size to pass through. The size of the apertures can be adjusted to control the size of the particles that are allowed to pass through.

Advantages: A vibrating screen for sand and gravel aggregate offers several advantages:

- Efficient Separation: It efficiently separates the larger particles from the smaller ones, ensuring a uniform mixture of materials.

- High Capacity: Vibrating screens are capable of handling large volumes of material, making them suitable for high-capacity operations.

- Versatility: They can be used for a wide range of applications, including screening aggregates for construction, separating recyclable materials, and dewatering wet materials.

- Low Maintenance: With proper maintenance, vibrating screens are durable and reliable equipment with low operating costs.

In the construction and mining industries, a vibrating screen for sand and gravel aggregate is an indispensable piece of equipment. Its ability to efficiently separate materials based on size ensures the quality and uniformity of the final product. With robust design, efficient operation, and versatility, vibrating screens play a crucial role in various industrial processes.