In the bustling mining industry of Vietnam, crushers and screens play pivotal roles in the extraction of precious minerals and ores. As technology continues to advance, these essential pieces of equipment undergo significant innovations to enhance efficiency, productivity, and safety in mining operations.

Crushers, the workhorses of the mining sector, are instrumental in breaking down large rocks into smaller, more manageable sizes. These machines come in various types, each tailored to specific mining requirements. Jaw crushers, gyratory crushers, cone crushers, and impact crushers are among the commonly used variants, each offering unique capabilities suited for different tasks.

In Vietnam’s mining landscape, the utilization of crushers has witnessed remarkable advancements. Traditional crushers have evolved into sophisticated machinery equipped with cutting-edge features to optimize performance. Modern crushers boast higher throughput capacities, reduced maintenance requirements, and enhanced durability, thereby contributing to increased productivity and cost-effectiveness in mining operations.

One notable trend in Vietnam’s mining sector is the growing adoption of mobile crushers. These versatile units can be easily transported to different mining sites, allowing for greater flexibility in operations. Mobile crushers enable efficient crushing directly at the extraction site, minimizing the need for extensive material transportation and reducing operational costs.

Moreover, the integration of automation and digital technologies has revolutionized the functioning of crushers in Vietnamese mining operations. Automation systems enable remote monitoring and control of crusher parameters, ensuring optimal performance while prioritizing worker safety. Advanced sensors and real-time data analytics facilitate predictive maintenance, preemptively identifying potential equipment issues and minimizing downtime.

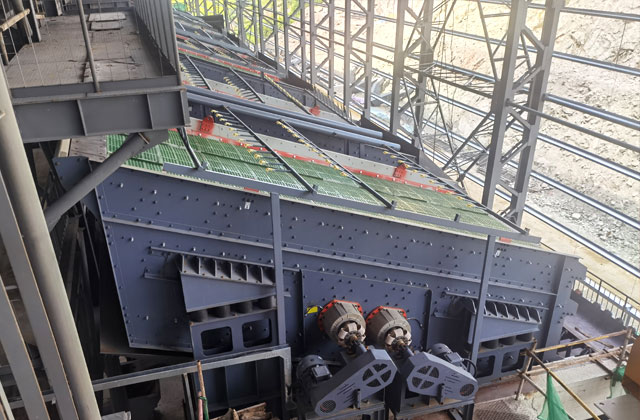

In parallel with crushers, screens play a crucial role in the mining process by classifying and separating materials of varying sizes. Vibrating screens, trommel screens, and inclined screens are commonly employed to efficiently segregate crushed materials, facilitating downstream processing and enhancing overall productivity.

In Vietnam, the evolution of screening technology has been driven by the demand for higher throughput rates and improved particle separation. Modern screens feature enhanced designs and materials, resulting in increased durability and screening efficiency. High-capacity screens equipped with advanced mechanisms ensure optimal material flow, minimizing blockages and downtime during operation.

Furthermore, the integration of modular and customizable screen systems has gained traction in Vietnam’s mining industry. These modular solutions offer flexibility in configuration, allowing miners to adapt screening processes to suit specific application requirements. Additionally, the incorporation of wear-resistant components extends the lifespan of screens, reducing maintenance costs and enhancing operational reliability.

The synergy between crushers and screens is essential for optimizing the efficiency of mineral processing operations in Vietnam. Seamless integration of these two components ensures a continuous flow of crushed materials through the screening process, leading to improved throughput and product quality.

In recent years, Vietnam has witnessed a surge in infrastructure development projects, driving the demand for construction materials such as aggregates, sand, and gravel. Crushers and screens play a pivotal role in meeting this growing demand by processing raw materials sourced from quarries and mines. The efficient operation of crushing and screening equipment ensures a steady supply of quality construction materials essential for infrastructure projects across Vietnam.