Selecting the right secondary crusher for a limestone crushing process is a crucial decision that can significantly impact the efficiency and overall success of the operation. A secondary crusher plays a key role in reducing the size of the mined limestone to a size suitable for further processing, whether it be for use in construction, agriculture, or other industrial applications. Several factors should be considered when choosing the appropriate secondary crusher for a limestone processing plant.

Feed Size:

The size of the limestone feed material is a critical factor in selecting the secondary crusher. Different crushers have varying capabilities in handling different feed sizes. It is essential to choose a crusher that can efficiently process the size of limestone produced by the primary crusher.

Production Requirements:

Understanding the production requirements and goals of the plant is crucial. Some secondary crushers are better suited for high-capacity scenarios, while others may be more appropriate for applications with lower production demands. Consider factors such as throughput and desired end-product specifications.

Crushing Ratio:

The crushing ratio, which is the ratio of the size of the feed material to the product, is an important parameter. Different crushers offer different crushing ratios, and the choice depends on the desired final product shape and size. A higher crushing ratio generally produces finer-sized end products.

Operational Costs:

Consideration of the operational costs associated with the secondary crusher is essential. This includes factors such as power consumption, maintenance requirements, and wear part costs. Selecting a crusher with lower operating costs can have a significant impact on the overall profitability of the operation.

Types of Secondary Crushers:

There are various types of secondary crushers suitable for limestone processing:

Impact Crushers: These crushers use impact force to break up the material. They are well suited for softer materials and produce a cubical product. Horizontal shaft impactors (HSI) and vertical shaft impactors (VSI) are common types.

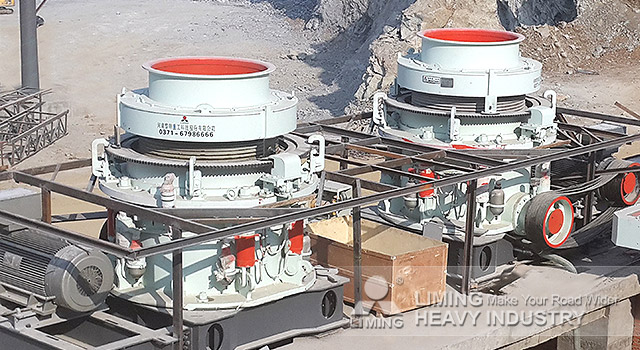

Cone Crushers: Cone crushers are suitable for secondary and tertiary crushing stages. They are known for their efficiency and are capable of producing a well-shaped product.

Jaw Crushers: While primarily used for primary crushing, some jaw crushers can also be used as secondary crushers. They are generally well-suited for handling tough, abrasive materials.

Compatibility with Downstream Equipment:

Ensure that the chosen secondary crusher is compatible with the downstream equipment, such as screens and conveyors. The entire crushing circuit should be designed to work seamlessly for optimal efficiency.

The selection of a secondary crusher for limestone processing involves a careful evaluation of various factors to ensure the chosen equipment aligns with the specific needs and goals of the operation. By considering factors such as feed size, production requirements, crushing ratio, operational costs, types of crushers, environmental impact, and compatibility with downstream equipment, operators can make an informed decision that positively impacts the overall efficiency and success of their limestone processing plant.