Ore grinding and processing through the use of ball mills is a crucial aspect in the mining industry. These mills are used to grind and blend materials for mineral processing, extracting valuable minerals from the ore. The process involves reducing the size of the ore particles, followed by further processing to extract the valuable minerals. Here is a comprehensive discussion on ore grinding and processing using ball mills.

Introduction to Ball Mills:

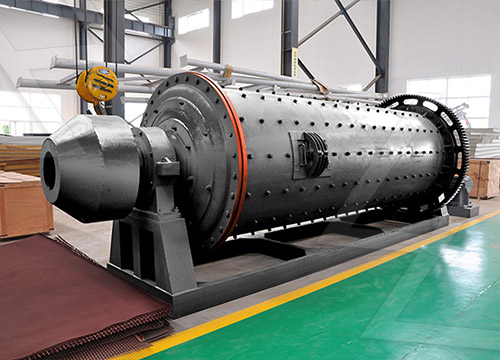

Ball mills are industrial equipment used for grinding and mixing materials such as ores, chemicals, ceramic raw materials, and paints. They work on the principle of impact and attrition: the size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be horizontal or at a small angle to the horizontal. The material to be ground is fed into the mill through the hollow shaft, and the grinding medium, usually steel balls, are put inside the cylinder.

Ore Grinding Process:

- Crushing and Grinding: The first step in ore processing involves crushing and grinding the ore to a fine size. This process prepares the ore for further grinding or for subsequent processing to extract the valuable minerals.

- Loading and Mixing: The ground ore is loaded into the ball mill, along with the grinding media, to initiate the grinding process. Proper mixing ensures that the ore particles are exposed to the grinding media, enhancing the efficiency of the process.

- Size Reduction: The ore particles undergo size reduction as they are impacted and crushed by the grinding media. The rotation of the mill causes the grinding media to cascade, thus reducing the size of the ore particles.

- Control and Monitoring: The process is carefully monitored to ensure optimal efficiency and to prevent over-grinding, which can lead to unnecessary energy consumption and reduced ore quality.

Ball Mill Design and Components:

- Shell: The shell of the ball mill is a welded structure that is divided into two or more chambers with different sizes of grinding media. The design of the shell depends on the specific requirements of the ore processing.

- Grinding Media: Steel balls are commonly used as grinding media. The size and type of grinding media depend on the characteristics of the ore and the desired fineness of the final product.

- Drive System: The ball mill is driven by a motor through a clutch, gearbox, and flexible coupling. The speed of the rotation can be controlled to optimize the grinding process.

- Liners: The inner surface of the mill is typically lined with an abrasion-resistant material to protect the mill shell from the impact of the grinding media.

Benefits of Ball Mills in Ore Processing:

- Efficient Size Reduction: Ball mills offer efficient size reduction, ensuring that the ore particles are finely ground for effective mineral extraction.

- Versatility: Ball mills can be used for both wet and dry grinding, making them versatile for various ore processing applications.

- Scalability: Ball mills come in various sizes and capacities, allowing for scalability based on the specific production requirements of the mining operation.

- Low Maintenance: Properly designed ball mills require minimal maintenance, reducing downtime and ensuring continuous ore processing.

Ore grinding and processing through ball mills is an essential process in the mining industry. Efficient size reduction, careful monitoring, and proper equipment design are critical for successful ore processing. With the right design and operational considerations, ball mills can contribute significantly to the extraction of valuable minerals, making them indispensable in the mining and mineral processing sector.