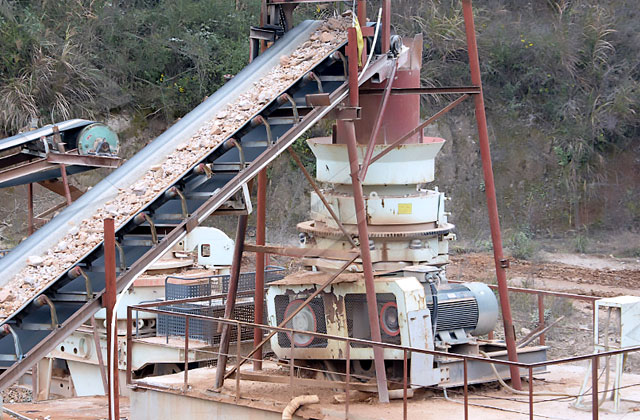

Aggregate crushers are essential pieces of equipment used in various construction and mining applications to break down large rocks into smaller, more manageable sizes. These crushers play a crucial role in the production of aggregates, which are used in the construction of roads, buildings, bridges, and other infrastructure projects. To ensure the efficient operation of aggregate crushers in Vietnam, high-quality crusher parts are essential.

Crusher parts are components that make up the internal workings of the crusher and contribute to its overall performance. These parts include the main frame, the crushing chamber, the mantle and concave liners, the eccentric and drive components, and various other smaller components. Ensuring that these parts are of top quality and properly maintained is critical for the effective functioning of aggregate crushers.

In Vietnam, where construction and infrastructure development are rapidly advancing, the demand for aggregates is high. This places an increased emphasis on the reliability and efficiency of aggregate crushers. High-quality crusher parts not only enhance the longevity of the equipment but also contribute to the safety of the operators and the productivity of the crushing process.

One of the primary crusher parts that require regular attention is the wear liners. These liners are subject to constant abrasion as rocks are crushed against them. Over time, wear liners can become worn and need replacement. Using high-quality wear liners made from durable materials can extend the lifespan of the liners and reduce downtime for maintenance.

Additionally, the proper maintenance of crusher parts is crucial. Regular inspections, lubrication, and timely replacement of worn parts can prevent unexpected breakdowns and production delays. Vietnam’s humid climate and varying operating conditions highlight the importance of maintenance routines to prevent corrosion and other forms of damage.

Choosing the right supplier for aggregate crusher parts is also essential. Reputable suppliers offer parts that are manufactured to strict standards, ensuring compatibility and reliability. These suppliers may also offer customization options to meet specific crusher requirements. Collaborating with a trusted supplier can streamline the process of acquiring and replacing crusher parts, contributing to uninterrupted operations.